Roll Reducing Machinery

The Oakley Roll Reducer Machines is designed to allow for elements to be reduced quickly, and for them to have a 3% to 7% greater element elongation. This can result in considerable cost savings in both tubing and MgO. Because the elements are not work-hardened as much as in traditional reducers, it is easier to obtain straight elements and there is less wear on the rolls.

- Faster Reducing Speeds

- Straighter Elements

- Accurate and Consistent Diameters

To Learn More About Our Roll Reducing Machine - Click the link below:

XLO Heavy Duty Roller Reducer Machine

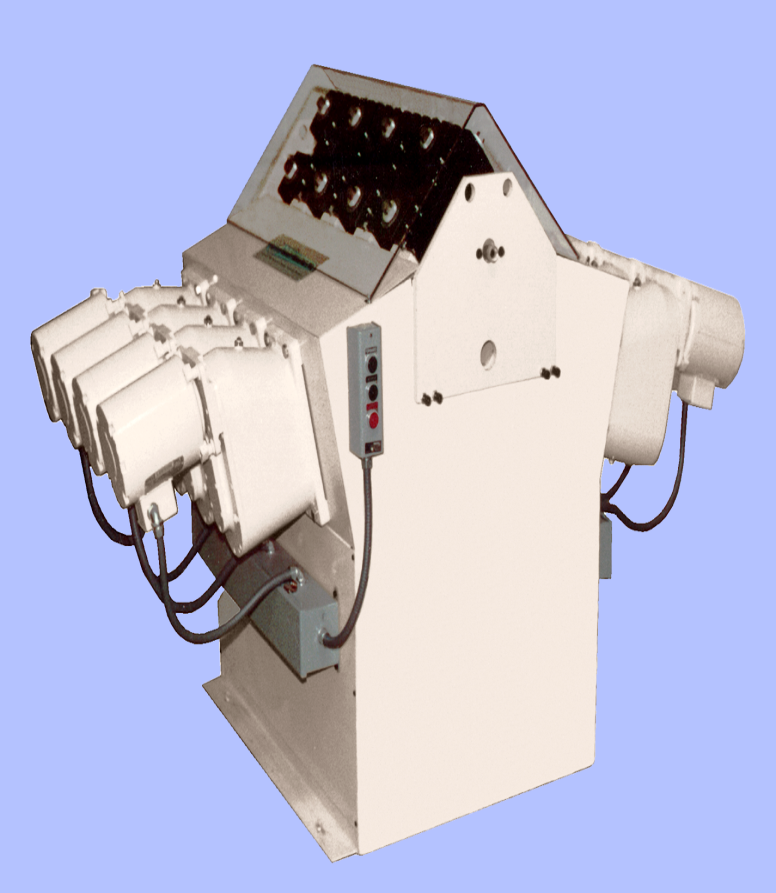

The Oakley XLO Heavy Duty Roll Reducer Machine is designed to accommodate larger element diameters, heavier wall thicknesses, and greater reductions that are normally associated with industrial heating elements .

- Reductions of 25% or more

- Quick Change Capability-Rolls and guide bushings can be changed over in 1 to 2 hours.

- Rolls can be provided with progressively larger diameters to increase element elongation.

To Learn More About Our XLO Roll Reducer Machine - Click the link below:

Roll Reducer Machine

XLO Heavy Duty Roller Reducer Machine