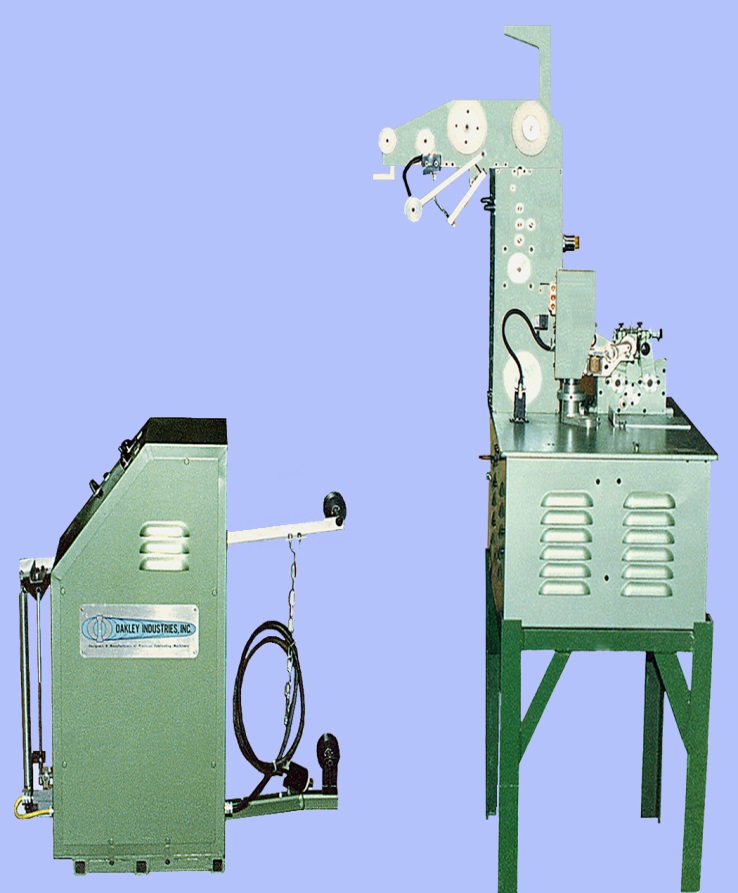

Oakley Helix Coil Winding Machines-Versions 1 & 2

The Oakley Helix Coil Winding Machines are designed for the proper manufacture of uniform coil wire so a consistent temperature can be maintained inside an element. Our machine will produce coils with very consistent resistance values and with open inside diameters for easy assembly to the terminal pins. Because these machines are fully automatic, no operator is required.

- It can make spiral coils from wire diameters from 0.1mm to 1.4mm (.004” to .055”).

- High-Speed winding with 0-8000rpm variable speed drive.

- Accurate OHM Control (+/- 1%)

- Single or 2-Wire (Tandem) coils

To Learn More About Our Coil-Winding Machine-(Version 1) - Click the link below:

To Learn More About Our Coil-Winding Machine-(Version 2) - Click the link below:

Oakley Automatic De-Spooling Machine

The Oakley De-Spooling Machine is designed for the unwinding of coil wire for those customers who use DIN 250 or DIN 355, we offer our automatic de-spooler. These spools of wire hold 20 kg. or 50 kg. (44 lbs. or 110 lbs.) respectively. Using these large spools of wire eliminates the need for frequently replacing spools when producing a large quantity of coils.

- Combination drive/brake motor with adjustable brake tensioning.

- Drive Motor turns the spool of wire to overcome inertia and prevent the wire from breaking.

To Learn More About Our Coil Winding Machine & Automatic De-Spooling Machine - Click the link below:

Helix Coil Winding Machine

Automatic De-Spooling Machine