Trim Machinery

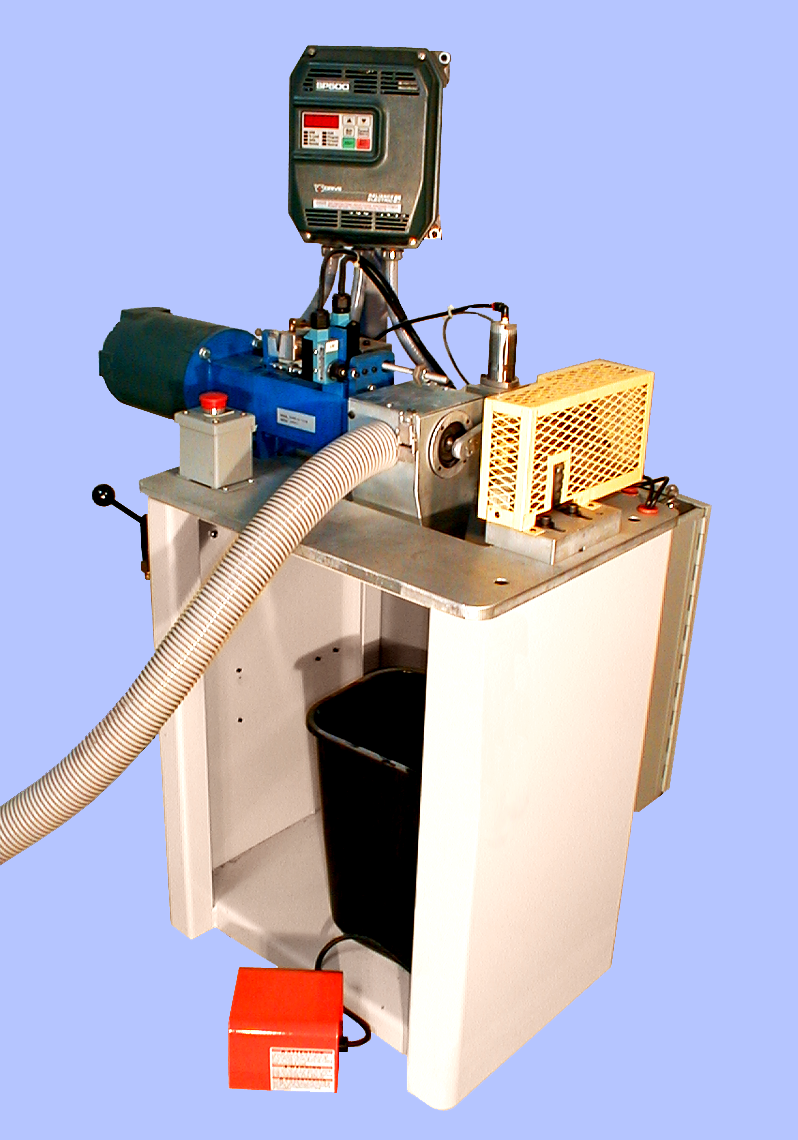

The Oakley Single End Trim Machine is designed as a hand loaded unit that clamps the elements and strips back the MgO and the tubular sheath to expose the predetermined terminal pin length. It trims one end of the element at a time, and the elements are removed manually from the machine. This unit is intended for medium to small production levels.

- Inexpensive end finishing for elements

- Simple adjustment for both element and trim length

- Adjustable feed rate

- Special design cutter head provides for fast and easy setup

Double End Trim Machine

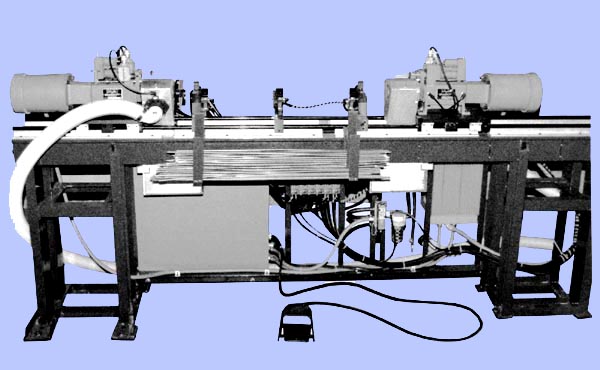

The Oakley Double End Trim Machine is designed similar in operation, but because both ends of the element are trimmed simultaneously and also because the elements are automatically ejected, it has a higher production rate. The operator loads the element into guide blocks and pushes it against a disappearing stop. The element is then clamped, the gage disappears, the element is trimmed at both ends, and then it is automatically ejected.

- Maximum element lengths from 600mm to 3650mm (2 to 12 feet)

- Trim heads are mounted on rails for simple and fast length adjustments.

- Production rate averages between 500 to 800 complete elements per hour

To Learn More About Our Trim Machine - Click the link below:

Single End Trim Machine

Double End Trim Machine