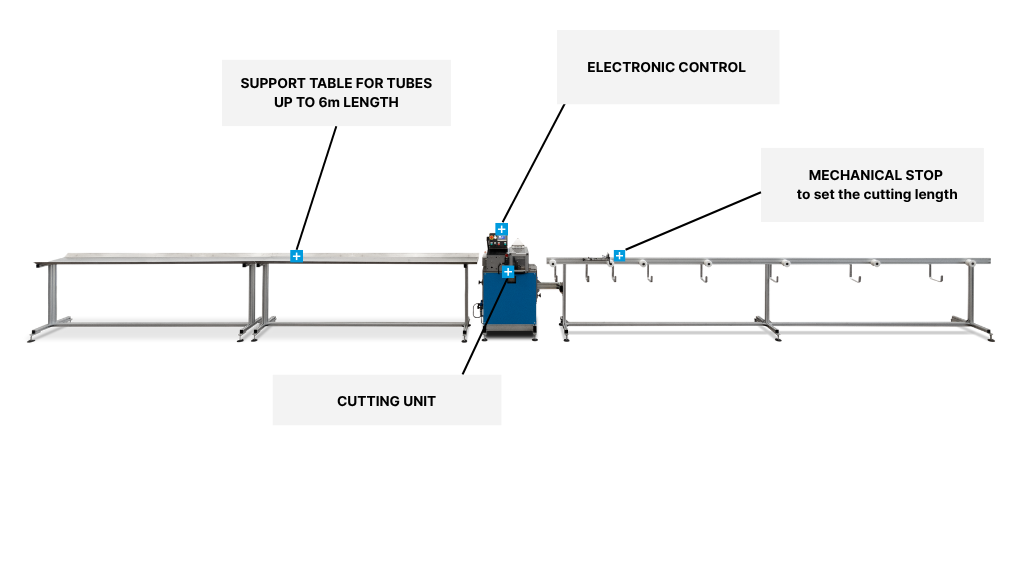

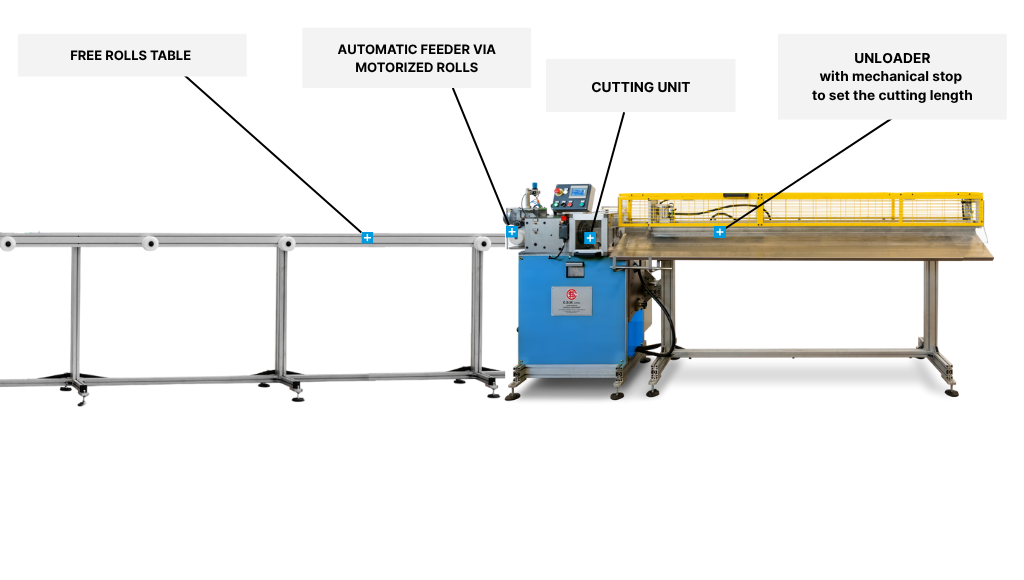

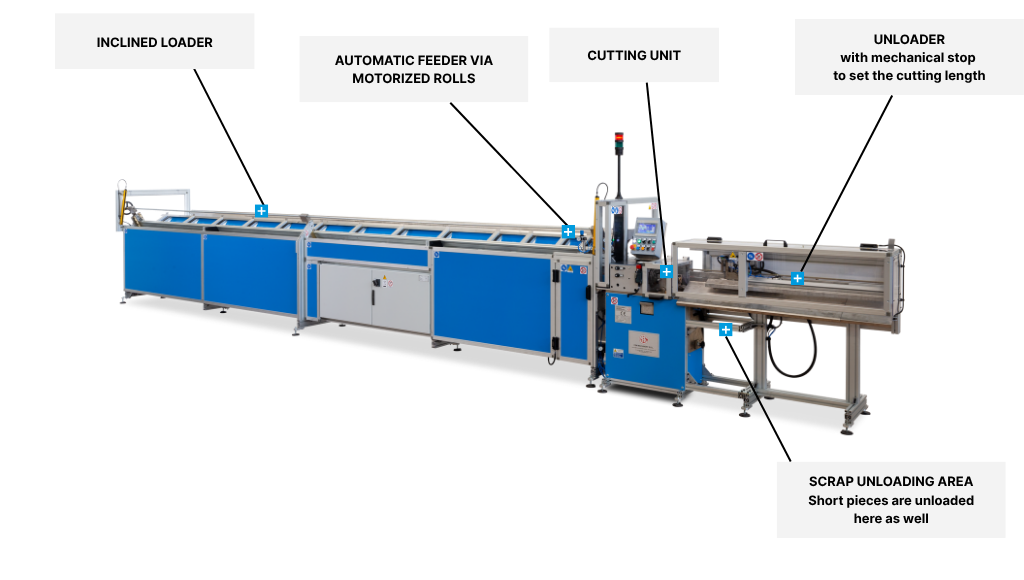

Tube cutting lines

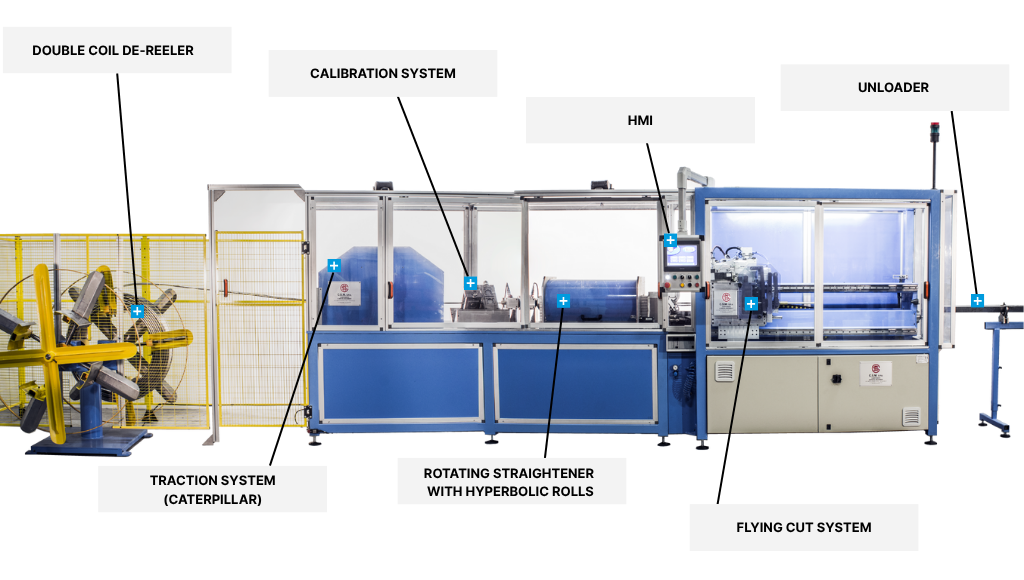

Drawing on extensive expertise in stainless steel tube cutting, Oakley Industrial Machinery designs and manufactures advanced tube cutting lines engineered to meet every customer’s production and quality requirement.

Our machinery for cutting tubes combines flexibility and precision, delivering high-volume tube/pipes cut performance across a wide range of materials — including stainless steel, steel, copper, aluminium, CuNi, incoloy and brass.

With multiple cutting technologies, different automation levels for tubes in straight lengths and a cutting line for tubes in coils, Oakley provides complete, efficient, and tailor-made solutions for every tube cutting application.

Cutting systems

At Oakley Industrial Machinery, we offer two advanced tube cutting systems in order to best fit your production requirements: the orbital/score and pull-apart system and the saw cutting system.

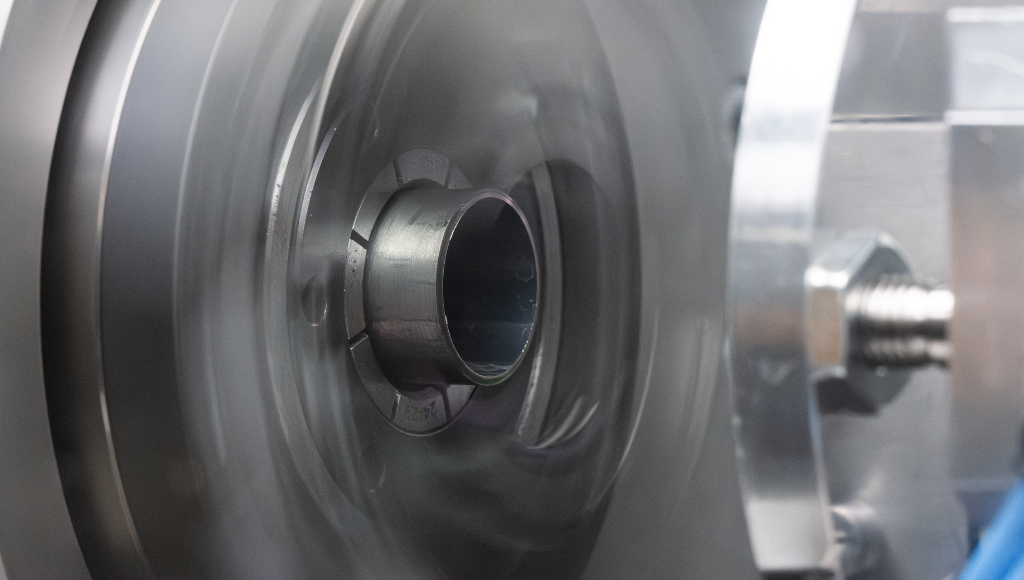

The score and pull-apart system is an orbital tube cutting process that uses either a rotary blade cutter or insert cutting technology. These methods progressively score the tube along a circular section of its wall thickness, thinning it until a clamp pulls-apart the segment. This system ensures chipless and burr-free tube cuts with perfectly smooth edges and no deformation.

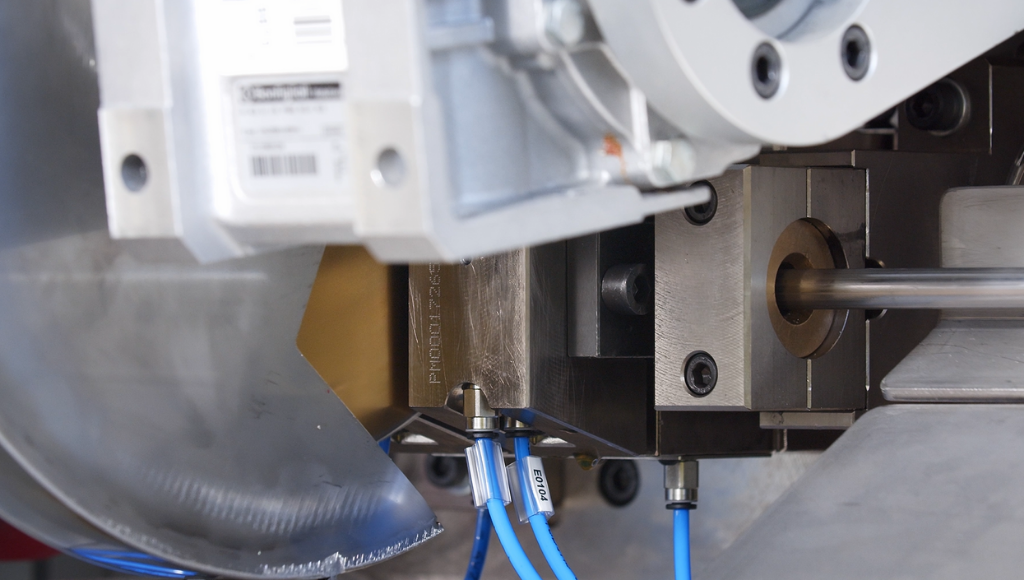

The saw cutting system uses a high-resistance circular blade rotating at high speed to deliver fast, precise, and clean tube cutting results. This technology can handle different tube materials and thicknesses while maintaining exact ninety-degree cuts. Built with durable components and advanced cutting techniques, it provides exceptional longevity, reliability, and consistent performance.