Oakley Terminal Pin Manufacturing

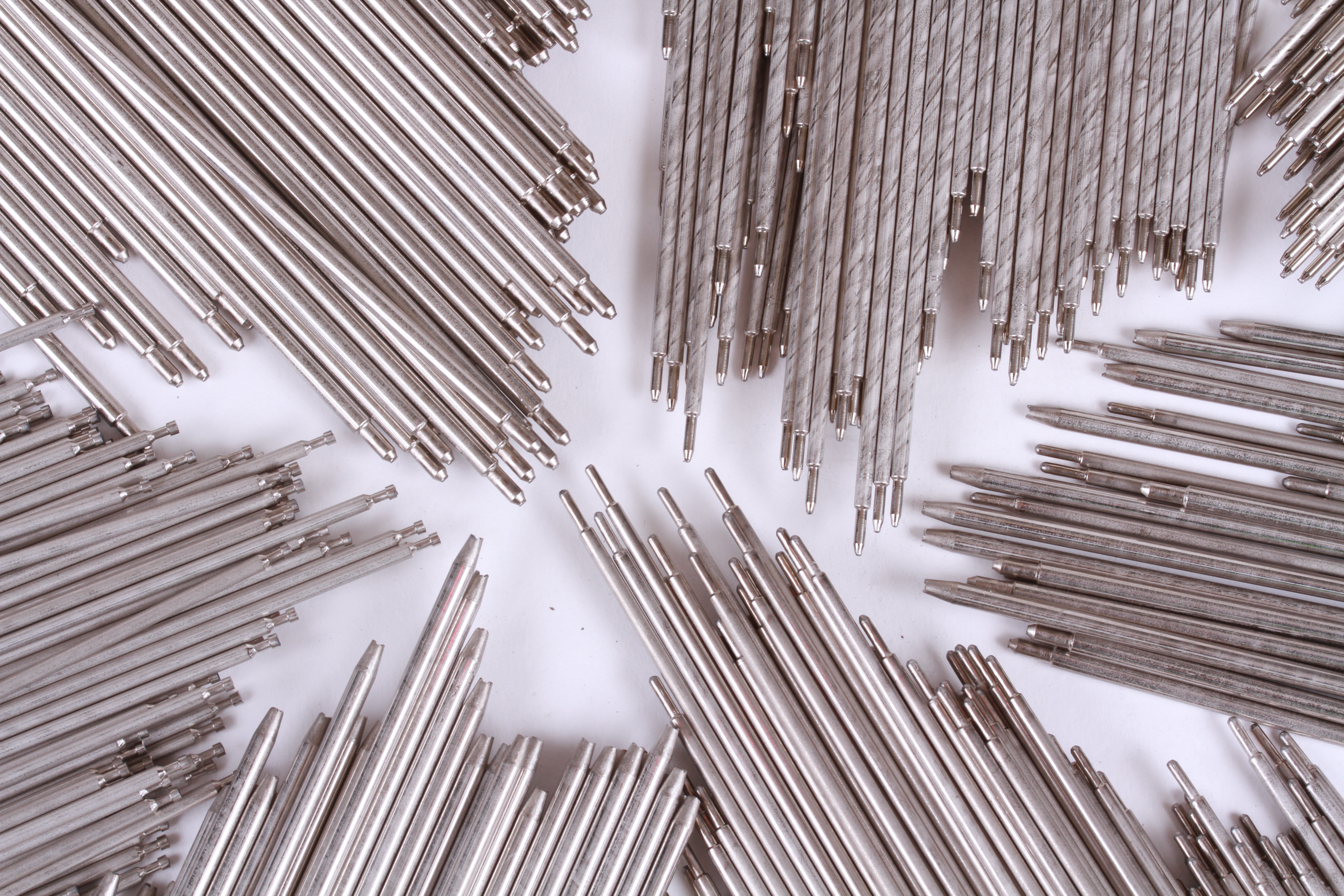

The Oakley Terminal Pin Division produces terminal pins that are used in tubular heating elements. We specialize in producing these terminal pins in high volumes with close tolerances. We currently supply a large majority of the heating element manufacturers in the United States, Canada, and Mexico, and we also export throughout the world. Our commitment to zero rejects and 100% on-time delivery has enabled us to forge solid partnerships with our many terminal pin customers.

- We supply our terminal pins from 2 types of wire. The first type is un-plated, low-carbon (C-1008) mild steel. The second type is a pre-plated material that has an inner core of the same low-carbon steel but then has a 2% by weight coating of nickel. Both wires have tensile strengths from 60,000 to 75,000 PSI.

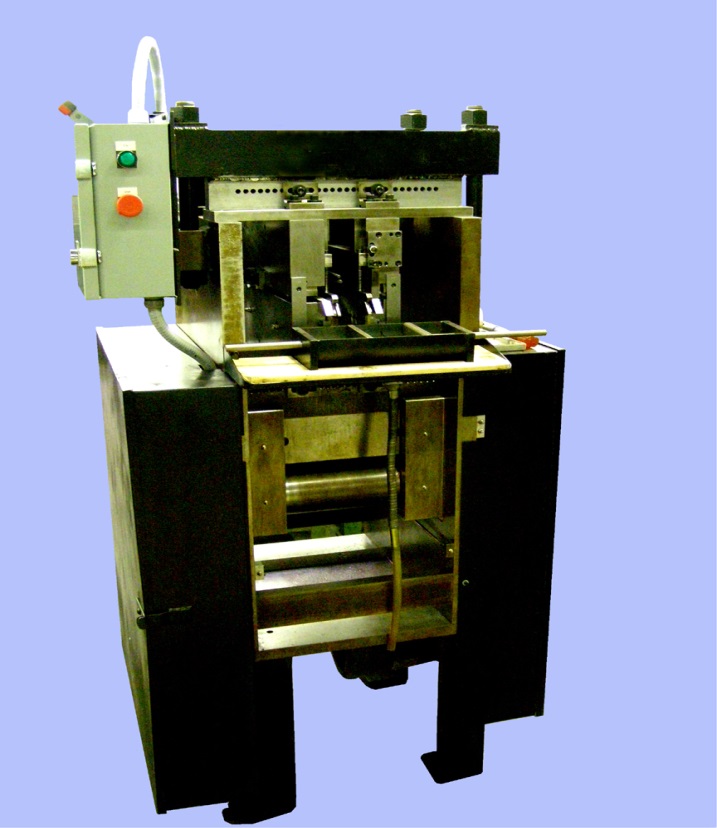

- We use specially designed cold-forming machines to produce our pins. These machines hold much closer tolerances than screw machines that are commonly used to make these pins. The cold-forming process allows us to use a softer wire with a lower tensile strength that makes welding the pin to coil assemblies much easier.

- The pre-plated nickel wire we use has many advantages for element manufacturers. First, the nickel coating is applied when the wire is still in rod form. The wire is then drawn down to the final size and the nickel coating becomes embedded in the steel material. Then, because we are cold-forming the parts, the nickel coating is not removed, but rather it is further embedded. The end result is that the nickel coating on our pins is impervious to peeling or flaking off and will withstand temperatures to 1200∞ C (2200∞ F) without melting away or discoloring. The nickel also greatly enhances the welding of the pins to the coils.

To Learn More See Our Terminal Pins Division Brochure - Click the link below:

Terminal Pins

Terminal Pin Machine